Car guy through and through, have a few pretty neat projects over the past couple years and really not a fan of the mainstream. I am 35 and a steamfitter/ service manager by trade. My dad recently retired and we finished his 64 ranchero this year. We decided that next summer we need to take a major road trip, kind of a trip of a lifetime if you will. Now I needed something cool to take on this road trip, something that is not another c 10 or a nova or a mustang.

I am a huge foxbody mustng fan, have owned several of them in the past from all different years. I would not call myself a ford guy though, purist probably want to turn away right now.

Started to search for an early bumpside F100 shortbed in descent body shape. I found a 68 white shortbed, clean with a dent on the passenger side of the bed. No motor in it but it was in the bed.

So the journey begins.

We loaded up the trailer and headed from home here in Portland down to Grants pass. Truck was exactly what he said so we paid the man, loaded it up on the trailer and headed for the house.

Finally got it in the garage after our big Alaska adventure and got to work. Pulled off the front sheetmetal, got it up on stands and proceeded to chop the frontend out from under it.

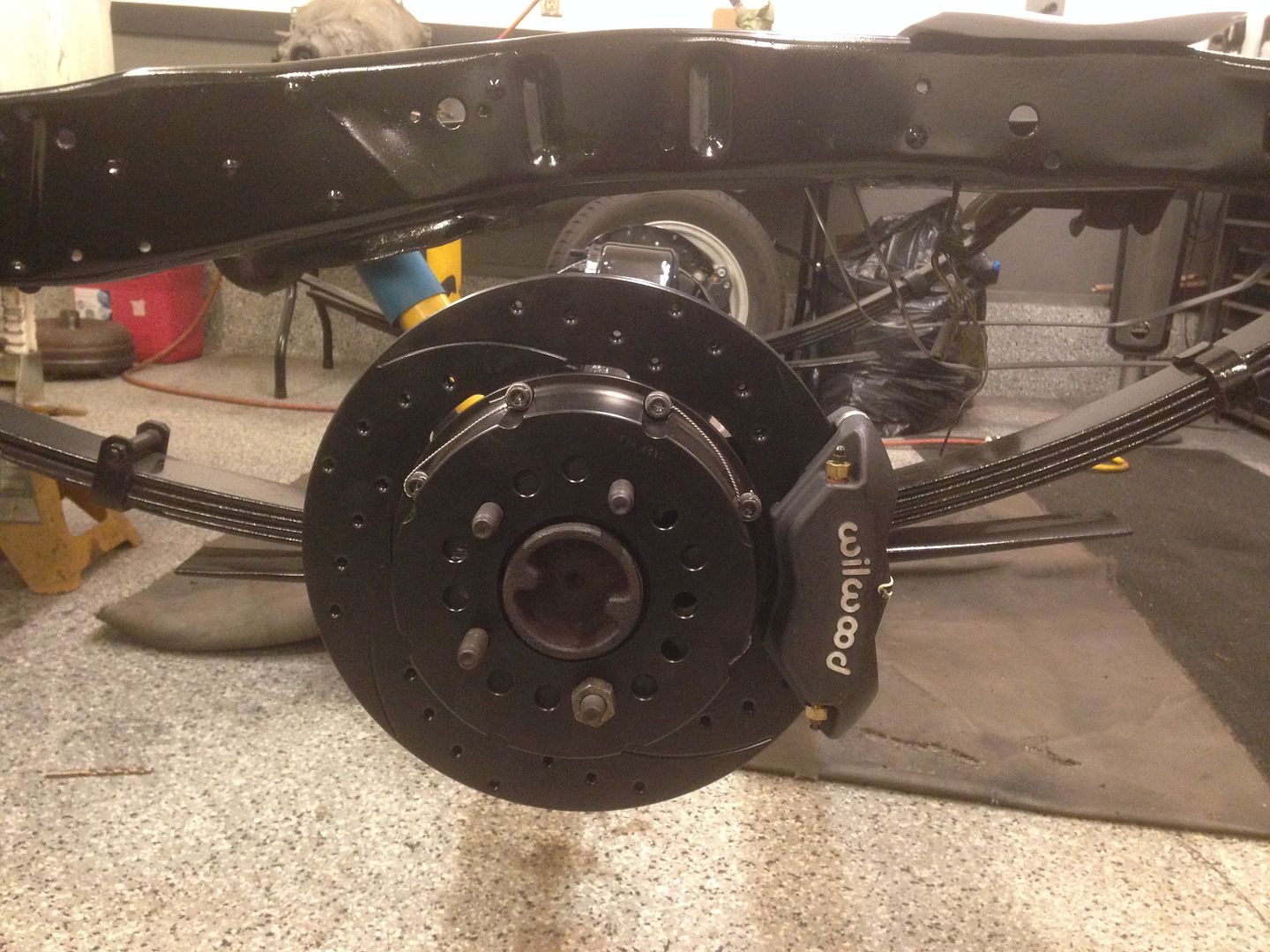

Once I was down to some framerails I started to mockup the 2003 crown vic stuff I picked up in Seattle, pretty easy stuff really, ran some .25 wall tubing through the framerails and burned in the mounts.

Got the frontend hung under there and built some tabs for the rear trailing arms and got those burned on there as well.

So, pretty sure here is where you all are going to turn your heads in disgust, but hear me out. This is a budget project, and needs to stay within reason and I am very familiar with GM drivetrain. So, this is getting a 6.0 lq4 from a 2003 hummer with a 4l80E backed up behind it.

Power will be assisted with a Borg Warner s480 turbo, 80 lb injectors, circle d triple disc full billet converter and a HD-2 shift kit. Looking for somewhere in the 700-800 WHP range.

So, I got to work getting the engine in place and building some motor mounts.

Engine is nice and low in the engine bay, tranny should work out nicely and the engine is staggered to the passenger side to assist with steering rack, booster and exhaust clearance.

Here are the engine mounts all finished up and ready to go for powder coating. I am using the OEM locations on the front K member with some poly bushings sandwiched in there, trying to leave some room for the 4" downpipe.

So, I got the brake booster and brackets from a 75 and swapped the pedal into my 68 assembly, pulled everything I could from the firewall and dropped all that stuff off at the powder coater on Monday and that gets us up to speed for the weekend.

Hope to finish any work on the firewall and get that shot with some paint so things can start going back together.

Hope at least a few of you folks follow along, should be a fun little winter project.

Sean