There is a small, round, red, indicator light labeled "brake". It is at the far drivers side, low on the dash, near my knees, close to the door. It has been lit since forever. I bought my truck and this light was lit and still continues to be lit. What does this indicator indicate? Is there something I need to be doing because this light is on?

What does the round "Brake" light mean?

Moderator: FORDification

-

pigeonbus

- New Member

- Posts: 3

- Joined: Thu Aug 14, 2014 8:48 pm

What does the round "Brake" light mean?

What does the round "Brake" light mean?

I have a 1968 F-100 240 I-6, Manual Steering, No power brakes, No A/C, No anything.

There is a small, round, red, indicator light labeled "brake". It is at the far drivers side, low on the dash, near my knees, close to the door. It has been lit since forever. I bought my truck and this light was lit and still continues to be lit. What does this indicator indicate? Is there something I need to be doing because this light is on?

There is a small, round, red, indicator light labeled "brake". It is at the far drivers side, low on the dash, near my knees, close to the door. It has been lit since forever. I bought my truck and this light was lit and still continues to be lit. What does this indicator indicate? Is there something I need to be doing because this light is on?

- Mancar1

- 100% FORDified!

- Posts: 5390

- Joined: Thu Jun 10, 2010 8:13 am

- Location: USS Gramps Garage (DD-727) Tehama County, Northern Ca.

Re: What does the round "Brake" light mean?

It is your break warning light.

It is indicating that something is not right with your break system.

mine was on when I bought my 68.

My breaks were wore out. Rebuilding my break system took care of the light being on.

It is indicating that something is not right with your break system.

mine was on when I bought my 68.

My breaks were wore out. Rebuilding my break system took care of the light being on.

May your sails stay full, and your knots not slip. Unless a slip knot.

Once I thought I was wrong, but I was wrong.

Life is a banquet, and every days a feast.

68 F-250 CS 390 C-6 P/S A/C front disc. 2nd owner.

2016 GMC Terrain Denali 301 HP V-6 AWD.

2009 Silverado Crew Cab, V-8, 4X4.

DD-727

DD-806

AE-35

LSD-39

AS-41

AR-8

Once I thought I was wrong, but I was wrong.

Life is a banquet, and every days a feast.

68 F-250 CS 390 C-6 P/S A/C front disc. 2nd owner.

2016 GMC Terrain Denali 301 HP V-6 AWD.

2009 Silverado Crew Cab, V-8, 4X4.

DD-727

DD-806

AE-35

LSD-39

AS-41

AR-8

- HIO Silver

- 100% FORDified!

- Posts: 1970

- Joined: Sat Jul 23, 2011 11:31 pm

- Location: Devil's Mountain, CA

Re: What does the round "Brake" light mean?

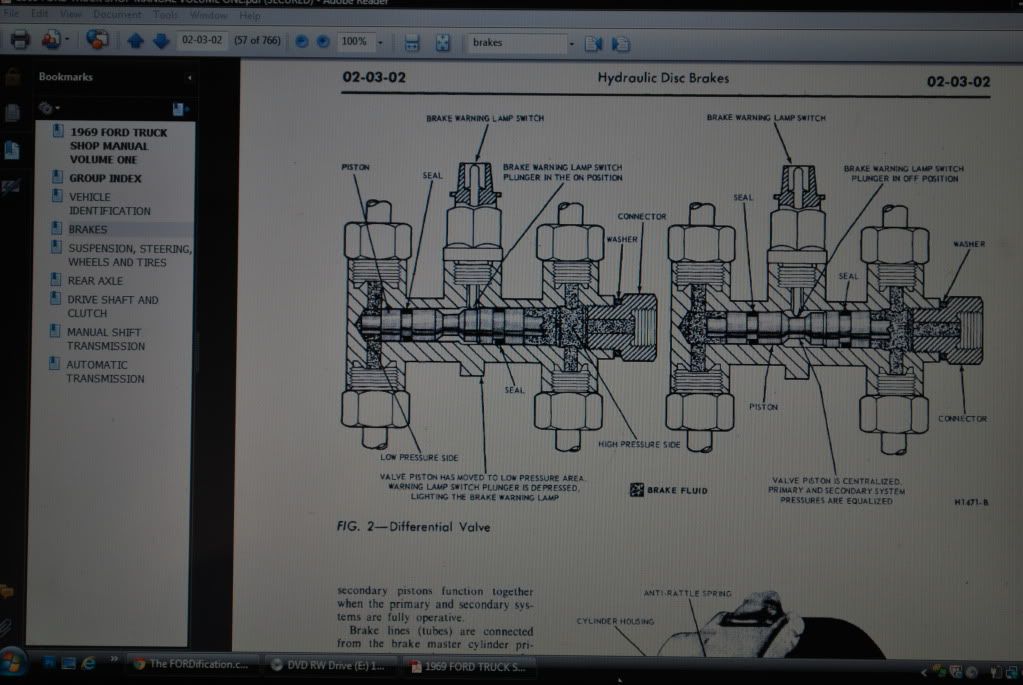

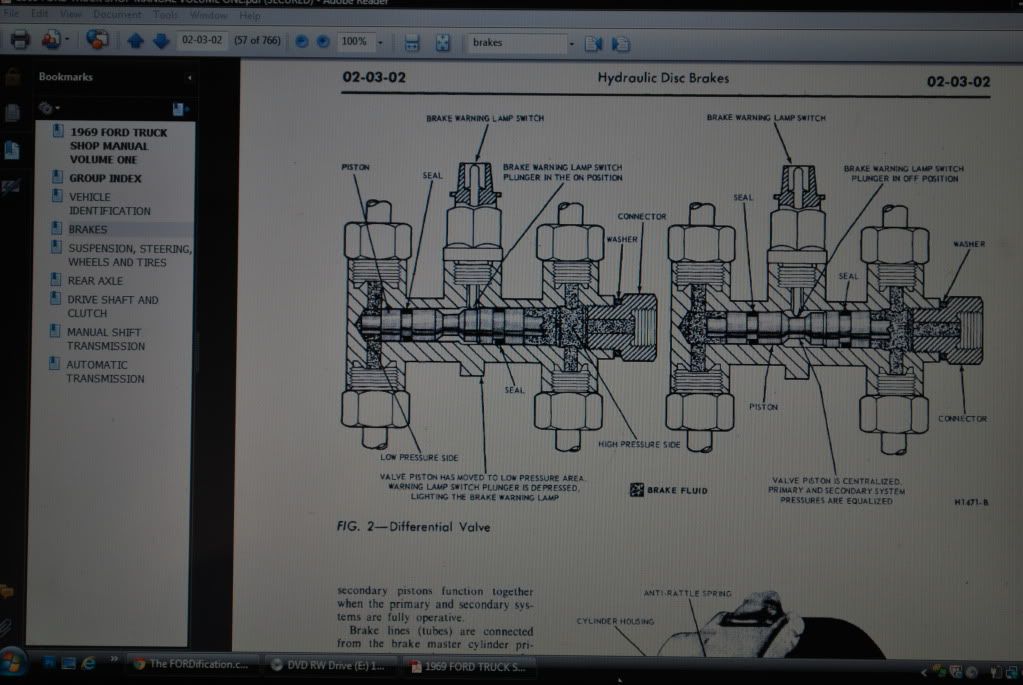

An illuminated light means the brake proportioning valve/distribution valve has defaulted to either the front brakes or the rear brakes. During bleeding procedures, a pin is supposed to be inserted through the switch to hold its internal piston in place. The pin is removed upon completion.

Under 'normal' conditions, the internal piston is centered but if pressure is lost in either the front or rear, then the piston is forced to one side and the light illuminates.

Study this cut-away to understand the principle:

Under 'normal' conditions, the internal piston is centered but if pressure is lost in either the front or rear, then the piston is forced to one side and the light illuminates.

Study this cut-away to understand the principle:

-

ultraranger

- Blue Oval Guru

- Posts: 1147

- Joined: Wed Apr 27, 2011 9:15 pm

- Location: Arkansas, Camden

Re: What does the round "Brake" light mean?

Your F-100 will just have a drum/drum pressure differential valve and not all the other internal functions of the disc/drum combination valve.

The spool inside the pressure differential valve has shifted because either there was a brake component failure or, the valve spool shifted while the brakes were being bled out.

The valve spool will have to be recentered before the warning light will go out and return full function to the brake circuits.

The spool inside the pressure differential valve has shifted because either there was a brake component failure or, the valve spool shifted while the brakes were being bled out.

The valve spool will have to be recentered before the warning light will go out and return full function to the brake circuits.

Steve

1969 SWB F100 Ranger. 240-6, C-4, 9" N-case 31-spline Traction-Lok w/3.50 gears.

1968 Mustang. My high school car. Owned since 1982.

2003 Azure Blue Mustang Mach1.

1969 SWB F100 Ranger. 240-6, C-4, 9" N-case 31-spline Traction-Lok w/3.50 gears.

1968 Mustang. My high school car. Owned since 1982.

2003 Azure Blue Mustang Mach1.

-

Bill Ramsey

- Preferred User

- Posts: 253

- Joined: Tue Sep 03, 2013 7:01 pm

- Location: San Diego

Re: What does the round "Brake" light mean?

How do you feset the valve?

1968 Highboy

1976 Highboy

1969 F250 Camper Special

1941 Dodge Power Wagon

1930 Model A Coupe (Hotrod)

1962 Fairlane 500 Sports Coupe

VW Sandrails

Honda ATC's

36' Diesel Pusher for roughing it.

1976 Highboy

1969 F250 Camper Special

1941 Dodge Power Wagon

1930 Model A Coupe (Hotrod)

1962 Fairlane 500 Sports Coupe

VW Sandrails

Honda ATC's

36' Diesel Pusher for roughing it.

-

ultraranger

- Blue Oval Guru

- Posts: 1147

- Joined: Wed Apr 27, 2011 9:15 pm

- Location: Arkansas, Camden

Re: What does the round "Brake" light mean?

Your drum/drum pressure differential valve should look like the one in the following photo. It will be located on the drivers side inner frame rail, just rearward of the steering gear box.

There will be (3) lines on one end and (2) lines on the other. The end with (3) lines is the primary side for the front brakes. The end with (2) lines is the secondary side for the rear brakes.

As long as there's equal pressure in the brake system, the pressure differential valve spool will remain centered. If there's a failure in the brake system (on the rear for example), where a hard line or flexible brake line ruptures or the wheel cylinder blows out, this will cause low pressure in the system to the secondary side of the valve and the higher pressure of the primary side of the valve will force the differential valve spool to shift to the lower pressure secondary side, which would turn the warning light on. This can also happen when you are bleeding the brakes out. The system doesn't know if it's a legitimate component failure or if you're just bleeding the brakes out. It just knows it senses a differential in brake pressure between the primary and secondary brake circuits, the spool moves to the low pressure side and the warning light comes on.

You will need to take the wiring connector off the plastic switch, sticking out of the valve, and unscrew the switch from the valve body to look in through the hole to see where the position of the detent (narrow part of the spool) is. The spool inside is hour glass shaped. The detent of the spool should be centered in the hole. You may need a mirror and a flashlight to see into the hole.

If you find the detent is off center, towards the secondary side (rear brake circuit) for example, then you will need to put the plastic switch back in the valve and reconnect the wiring connector to the switch. You'll have to crack a bleeder screw open on the primary side (front brakes). From inside the truck, turn the key to on and watch the warning light as you begin to slowly apply pressure to the brake pedal. This will build pressure on the secondary side of the brake system. The increasing pressure should get to a point that it forces the spool back to center. The instant the light goes off, get off the pedal or the spool will shift all the way over to the primary side and the problem will go from the rear circuit to the front circuit. This would probably be easier to do with two people.

Before you start the process of correcting the valve, this simple valve lock tool (in the following link) is a very good item to have to prevent this from happening when you are bleeding the brakes. It won't re-center the valve if it's already off-center to begin with but, it will keep it from moving in the future when you need to bleed the brakes. --It may be that during this process of re-centering it that you will have to re-bleed the brakes. If so, it will save you a lot of trouble now, AFTER you get the spool back to center.

https://www.musclecarresearch.com/brake-valve-tool

There will be (3) lines on one end and (2) lines on the other. The end with (3) lines is the primary side for the front brakes. The end with (2) lines is the secondary side for the rear brakes.

As long as there's equal pressure in the brake system, the pressure differential valve spool will remain centered. If there's a failure in the brake system (on the rear for example), where a hard line or flexible brake line ruptures or the wheel cylinder blows out, this will cause low pressure in the system to the secondary side of the valve and the higher pressure of the primary side of the valve will force the differential valve spool to shift to the lower pressure secondary side, which would turn the warning light on. This can also happen when you are bleeding the brakes out. The system doesn't know if it's a legitimate component failure or if you're just bleeding the brakes out. It just knows it senses a differential in brake pressure between the primary and secondary brake circuits, the spool moves to the low pressure side and the warning light comes on.

You will need to take the wiring connector off the plastic switch, sticking out of the valve, and unscrew the switch from the valve body to look in through the hole to see where the position of the detent (narrow part of the spool) is. The spool inside is hour glass shaped. The detent of the spool should be centered in the hole. You may need a mirror and a flashlight to see into the hole.

If you find the detent is off center, towards the secondary side (rear brake circuit) for example, then you will need to put the plastic switch back in the valve and reconnect the wiring connector to the switch. You'll have to crack a bleeder screw open on the primary side (front brakes). From inside the truck, turn the key to on and watch the warning light as you begin to slowly apply pressure to the brake pedal. This will build pressure on the secondary side of the brake system. The increasing pressure should get to a point that it forces the spool back to center. The instant the light goes off, get off the pedal or the spool will shift all the way over to the primary side and the problem will go from the rear circuit to the front circuit. This would probably be easier to do with two people.

Before you start the process of correcting the valve, this simple valve lock tool (in the following link) is a very good item to have to prevent this from happening when you are bleeding the brakes. It won't re-center the valve if it's already off-center to begin with but, it will keep it from moving in the future when you need to bleed the brakes. --It may be that during this process of re-centering it that you will have to re-bleed the brakes. If so, it will save you a lot of trouble now, AFTER you get the spool back to center.

https://www.musclecarresearch.com/brake-valve-tool

Steve

1969 SWB F100 Ranger. 240-6, C-4, 9" N-case 31-spline Traction-Lok w/3.50 gears.

1968 Mustang. My high school car. Owned since 1982.

2003 Azure Blue Mustang Mach1.

1969 SWB F100 Ranger. 240-6, C-4, 9" N-case 31-spline Traction-Lok w/3.50 gears.

1968 Mustang. My high school car. Owned since 1982.

2003 Azure Blue Mustang Mach1.

-

CharlaineC

- New Member

- Posts: 31

- Joined: Mon Sep 08, 2014 1:33 pm

Re: What does the round "Brake" light mean?

Ok so i'm having this same issue!! I couldnt find the dang gum valve so i crawled under Pearl and low and behold its mounted to a spot on the frame. and I dont even need to undo it to know the issue. I have a busted break line. wtf. and the po just crymped it closed.

-

tac

- Preferred User

- Posts: 443

- Joined: Mon Jun 03, 2013 10:50 am

- Location: Dallas/Ft. Worth

Re: What does the round "Brake" light mean?

Follow the brake lines off of the master cylinder. Its nested in the C channel of the frame behind the Steering box.