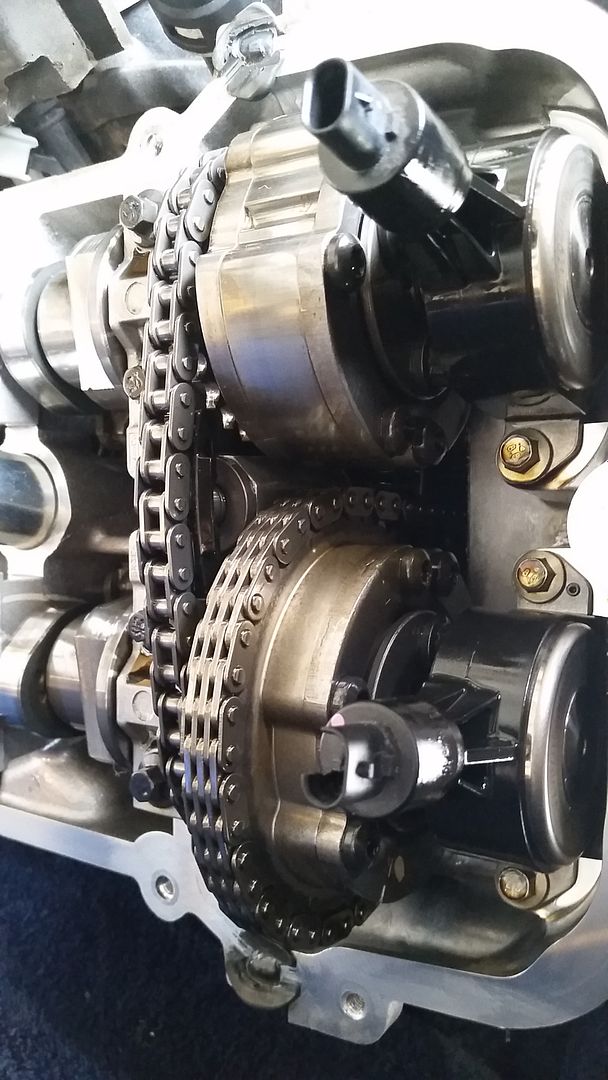

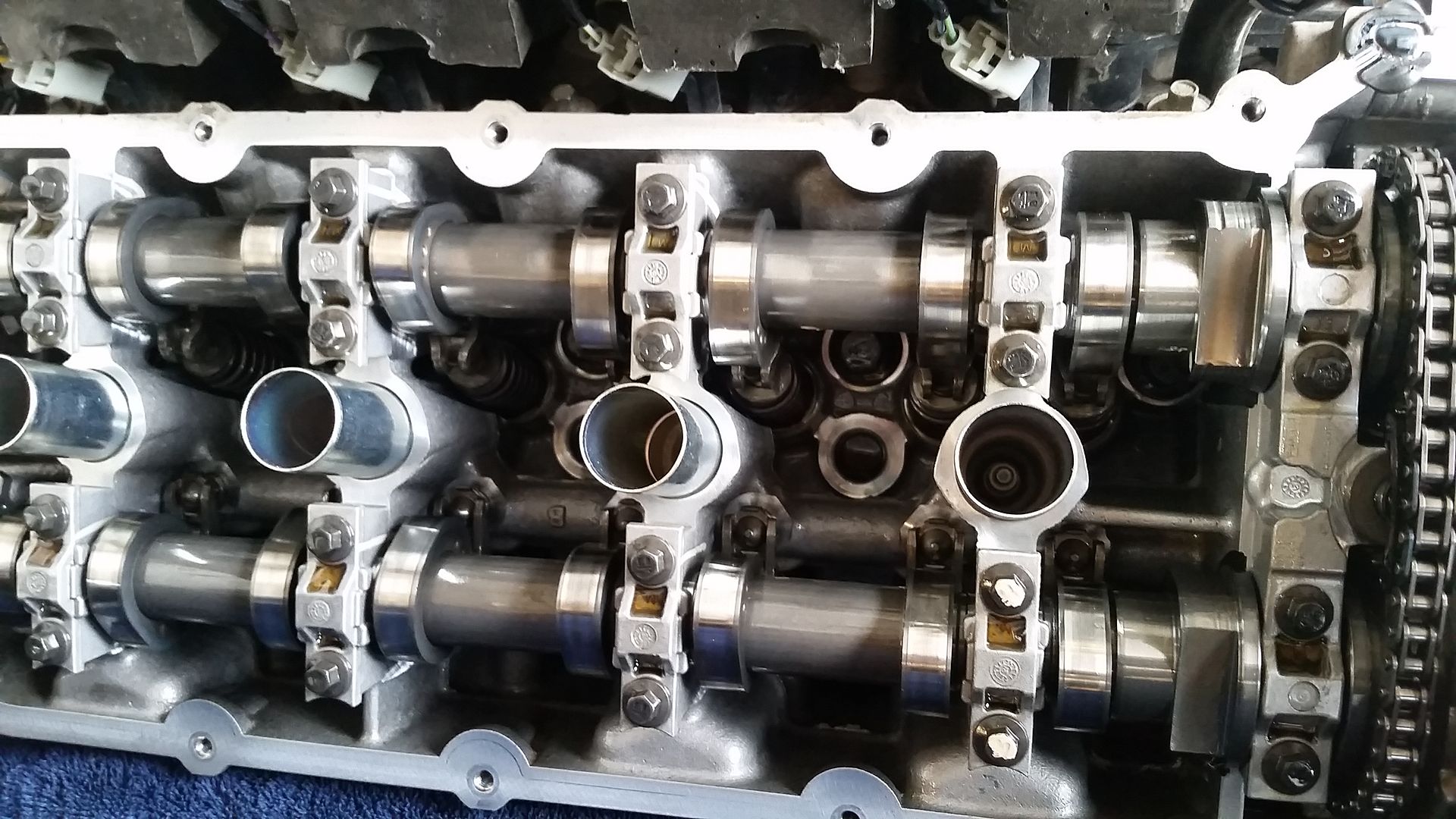

ablokzyl wrote:When donor car was hit, did it break the front cover? If it sounds like it is in the chains and you are seeing guide material on the chains, I would be thinking guides and tensioners would be in order.

Front cover is still very much in tact. No leaks, no cracks and no damage. The worst of the damage is a scratch on the water pump pulley.

ablokzyl wrote:Another thought. Are there any codes in memory? When it got hit, maybe one of the variable cam timing solenoids got jarred. They have been known to go bad on the 5.4 F-150s left and right causing all kinds of valve train noise.

No codes, different computer from when it was in the crash all together. I dont know how to check the solenoids.

ablokzyl wrote:Your exhaust timing solenoid looks broken in the last picture also

It is just the plastic housing on the one connector. The coil cover shows no signs of damage, the seal is in tact around the solenoid and the body of the solenoid is undamaged.....I am not saying this is not the problem but I dont know how to go any further here.

db204804 wrote:Hey awesome build as per usual! Just curious about the 22 sheets of Hush Mat... How many square feet is that? Just trying to figure out how much I will need.

-Dom

Each piece is 2 sq feet so about 40 or so. Keep in mind, that is nothing in the doors or the roof. I have 30 sheets and plan to use them all.

From last nights post...

We thought it was spark knock or Pre ignition being a really lean conditions so I ran some 110 octane through it last night, no change at all.

There is no other signs of damage other than the plastic on the one connector. The electrical connections appear to be just fine inside that one.

Pulled the serpentine belt off last night to rule out alternator, tensioner and water pump. Same noise.

Added in some hyper lube to the engine oil as I have heard good things about it same noise.

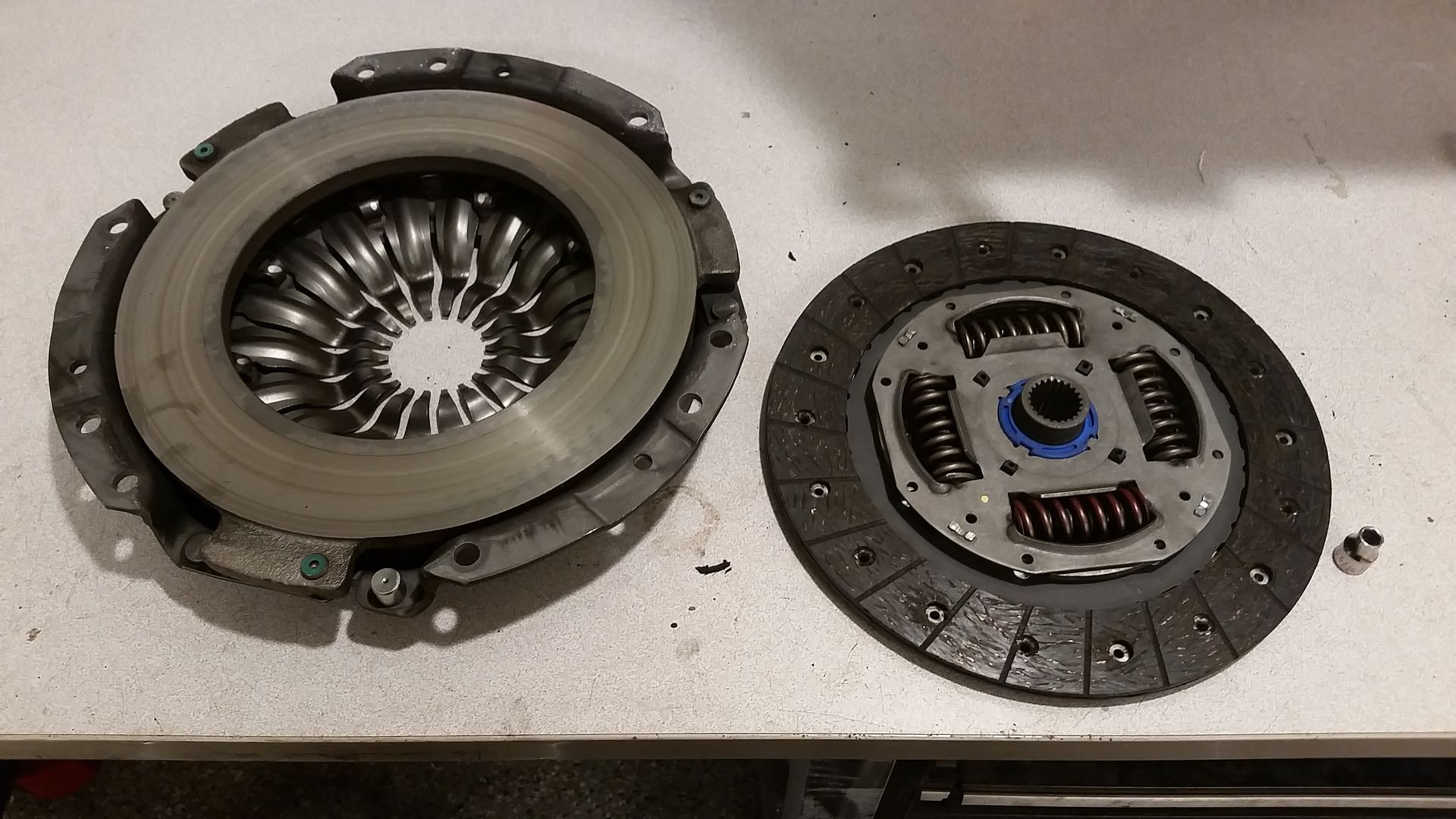

Picked up a stethoscope and got it good and warm and tried to pin point the tick. There is literally no noise from the engine. It was loudest near drivers side tire. So I started poking around with the stethoscope around the exhaust and frame then hit the bellhousing and the noise was very clear in the stethoscope.. tick tick tick.

I have no idea if the tick tick tick and clatter are related to each other, they sure sound similar though.

Push in clutch pedal, hot tick goes away.

Going to drain transmission fluid this am and flush and refill with redline MTL.

Interior has to get finished today and over to the upholsterer. Trip permit is going to run out and I need to get it registered so I am playing hooked from work for a little bit today.

Work peeps following along.....thanks for understanding =)

I'll report in in the MTL helped at all.

Sean

So....I had one dry day, and one day to get the upholstery done and get it to the upholstery guy.

Got the MTL swapped in, that was a nightmare by the way. It made no difference in the clatter. I raised up the rearend a little bit and went for a cruise. I put 10 gallons of fuel in the truck and drove it to the DMV.

Well its got a couple really big problems. The driveline vibration is bad. It does go away at some speed not sure what speed that is, it seemed to change around a little bit.

3rd gear, well it does not go into it all the time. Seemed to work about 80% of the time but twice at least I got a grind out of it.

The Clatter that I mentioned before and thought was pinging or detonation is clearly not. It is a mechanical issue, its present in any gear clutch in or out once its warm and has been driven a ways it will make it in the driveway.

Swapped in a brand new set of Motorcraft plugs just to rule that out.Also double checked the coil packs on each plug, verified operation as best I could. No difference.

So I am done with this thing for a bit. I am mentally destroyed between this and my actual work load.

I finished up all the work on the interior since I had a deadline with the upholstery guy tonight.

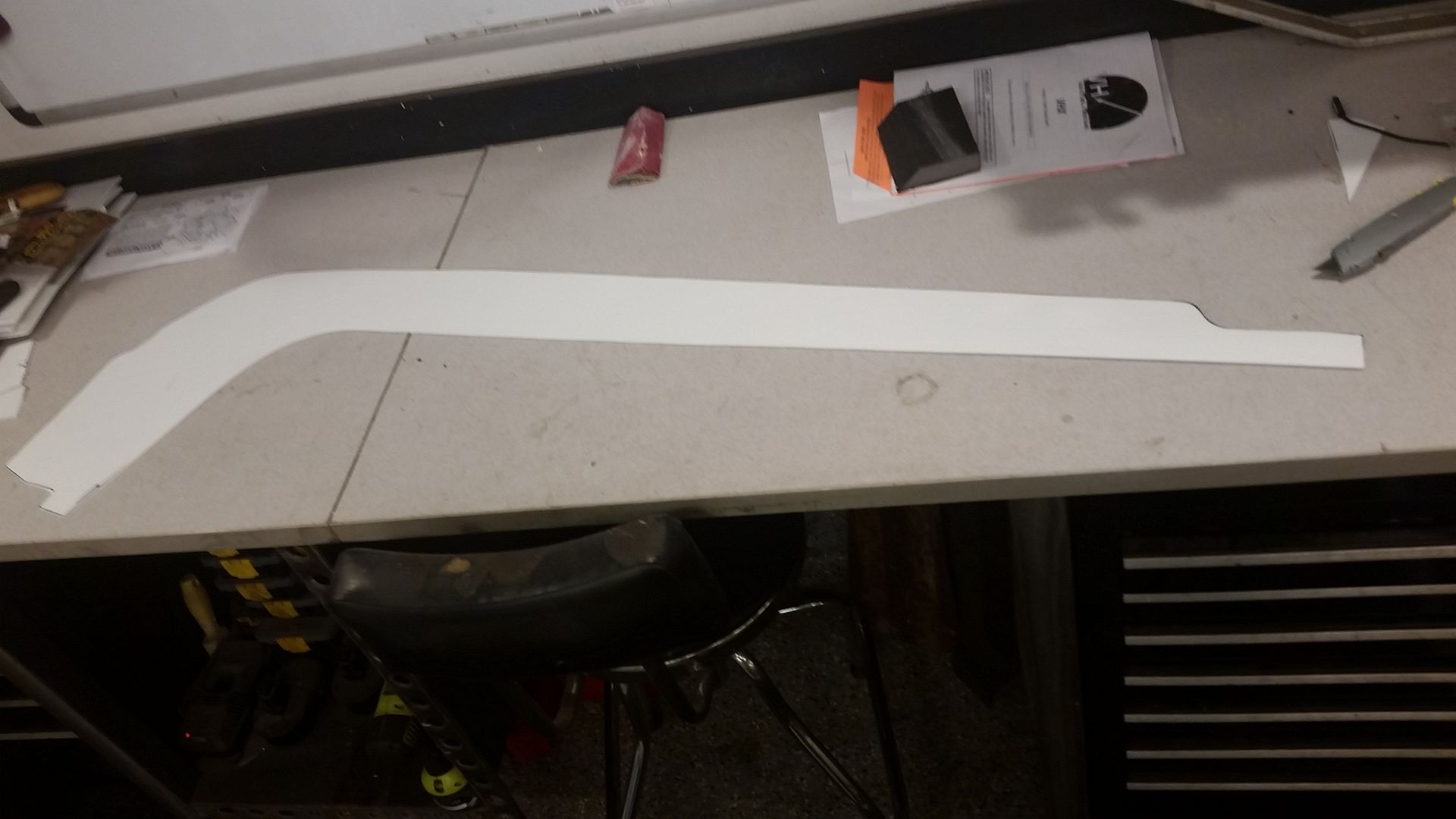

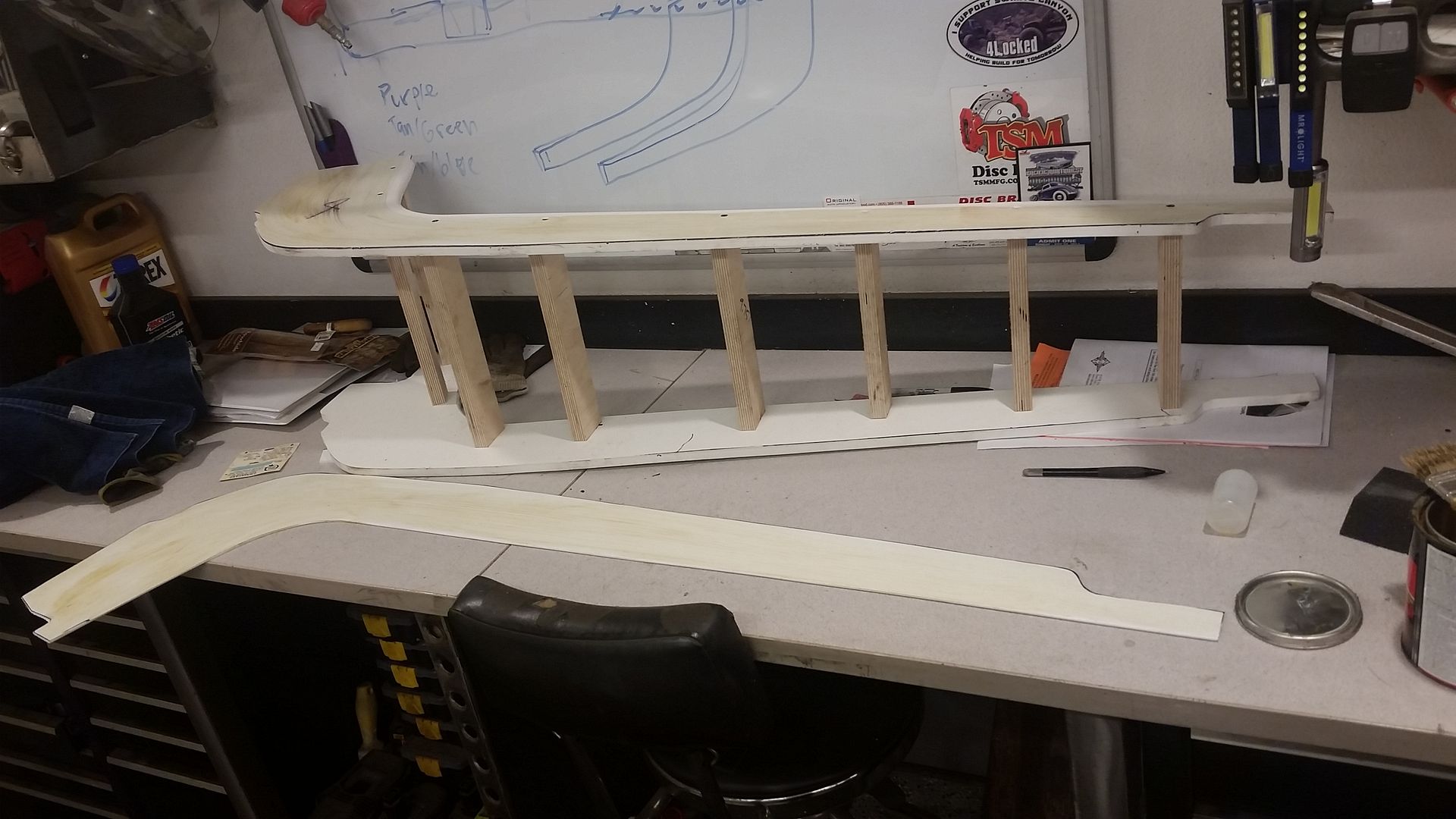

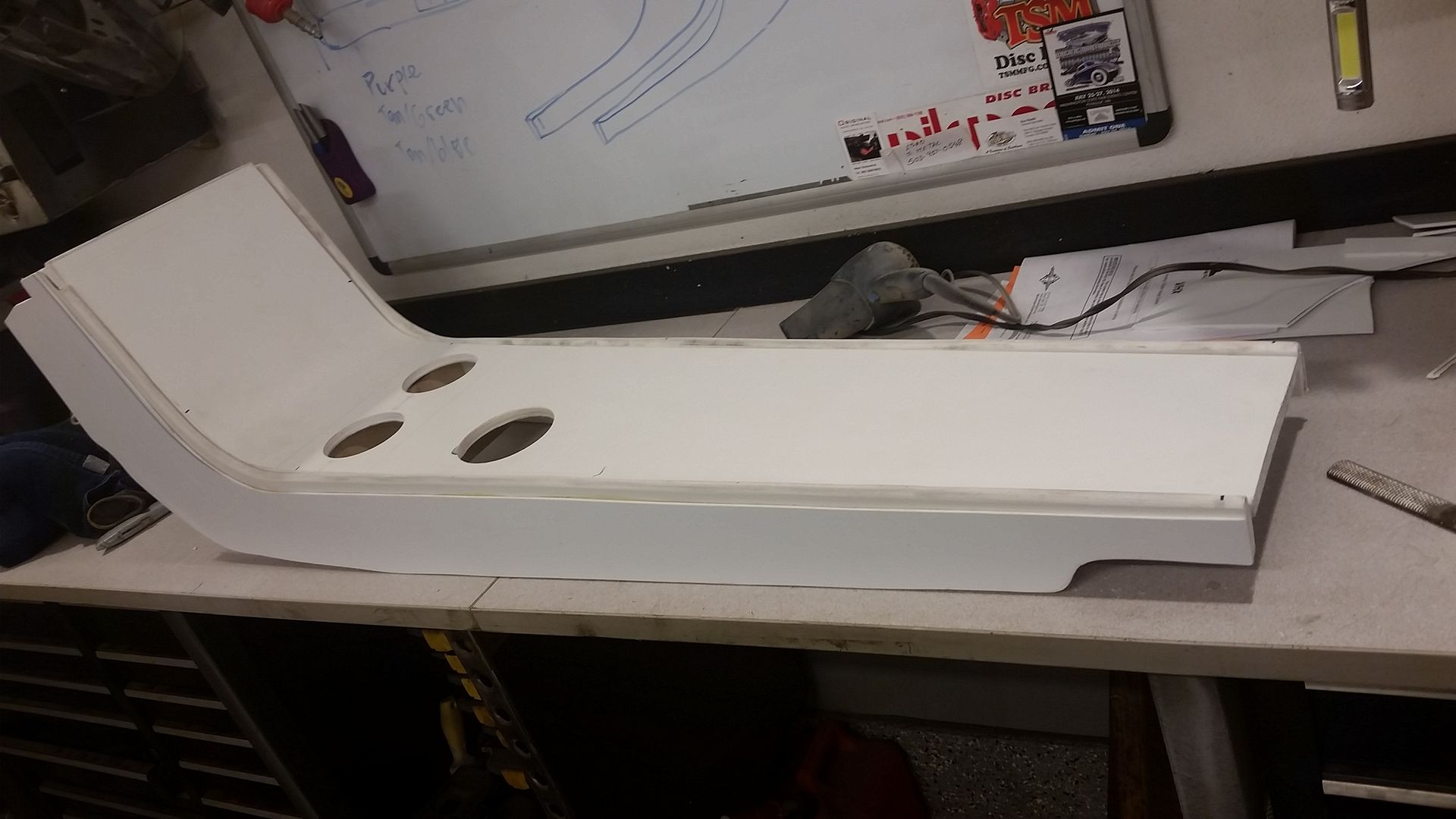

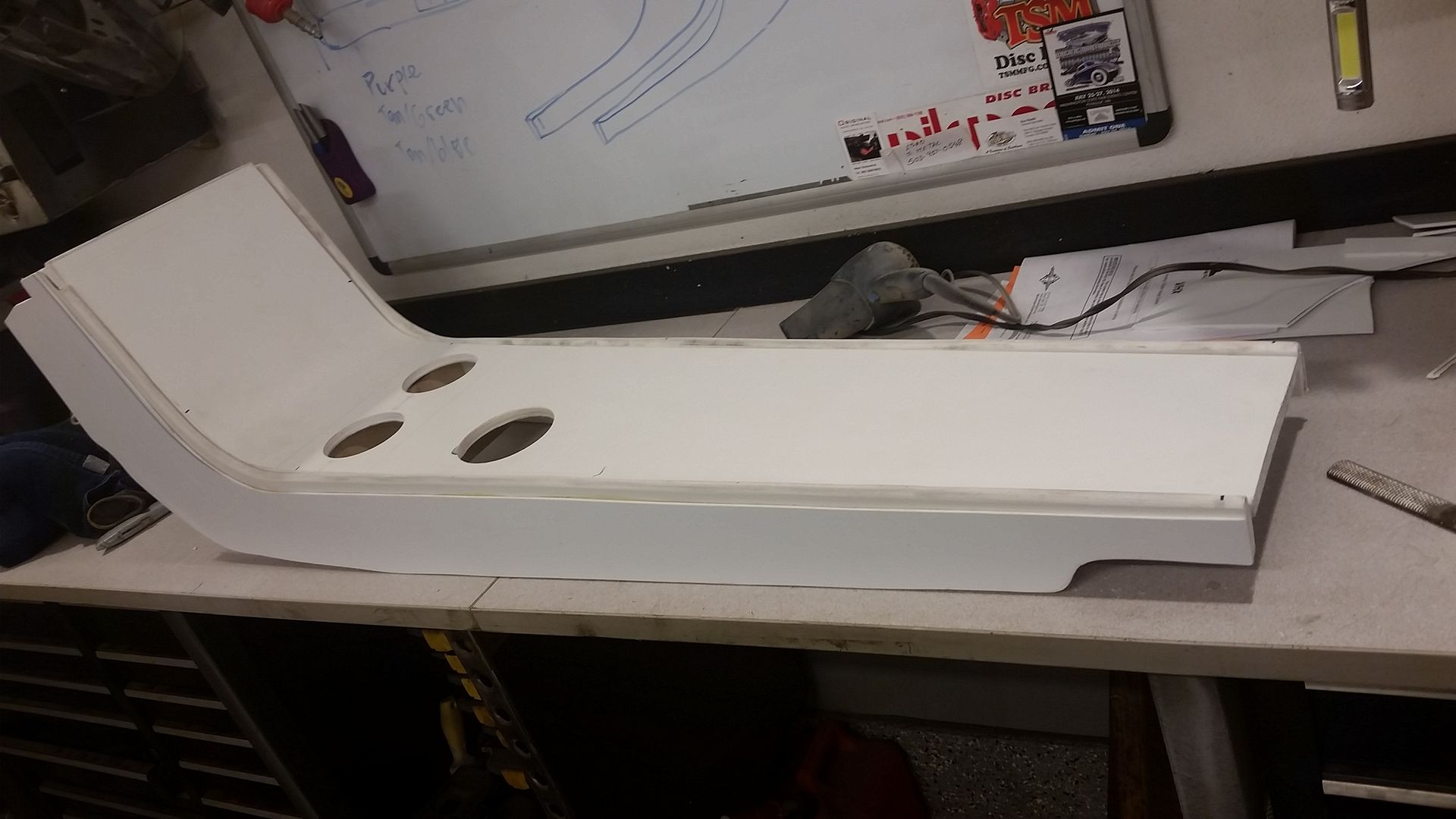

Here is what I ended up with on the console. I thought it turned out really well for a backyard shop.

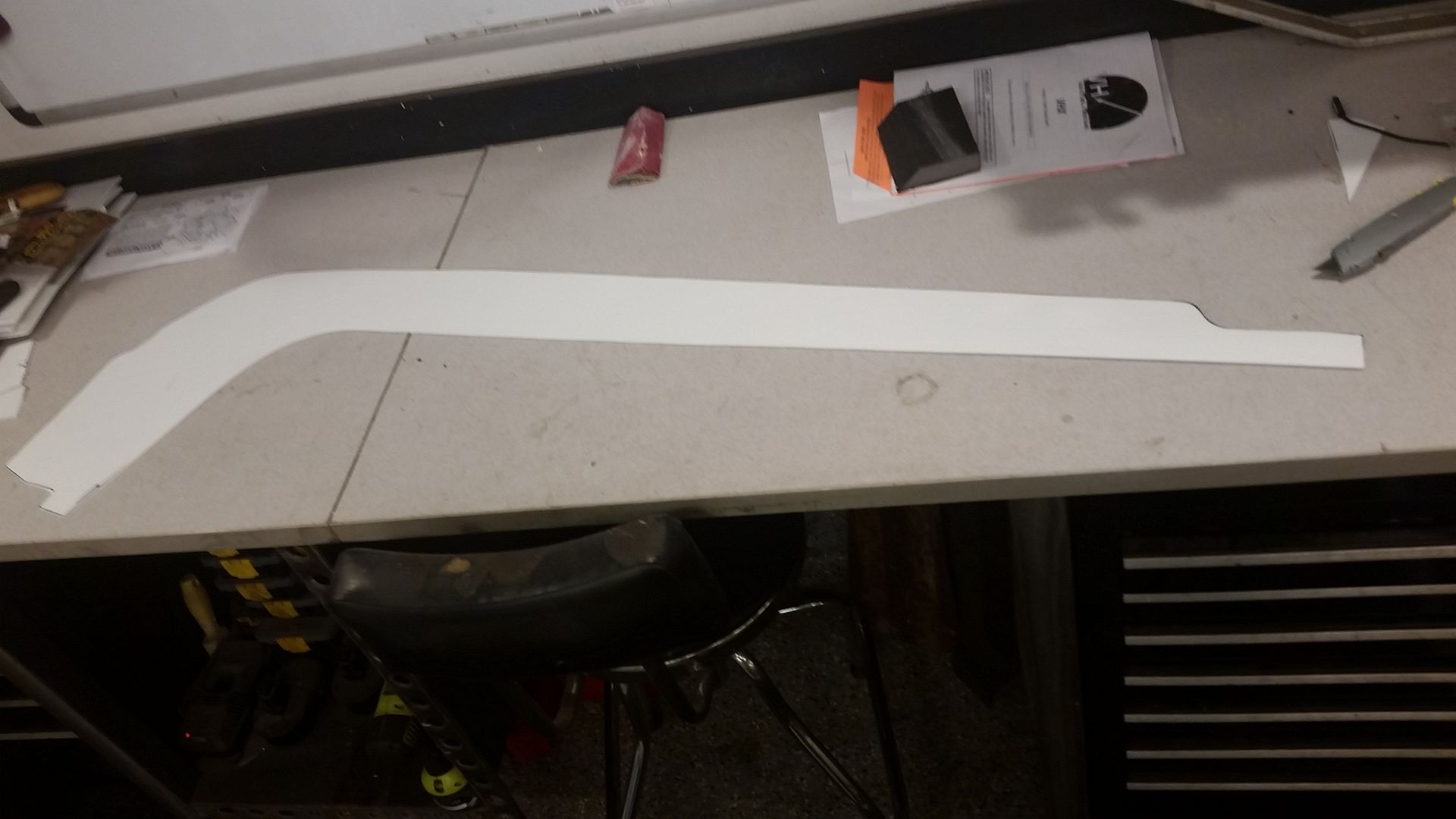

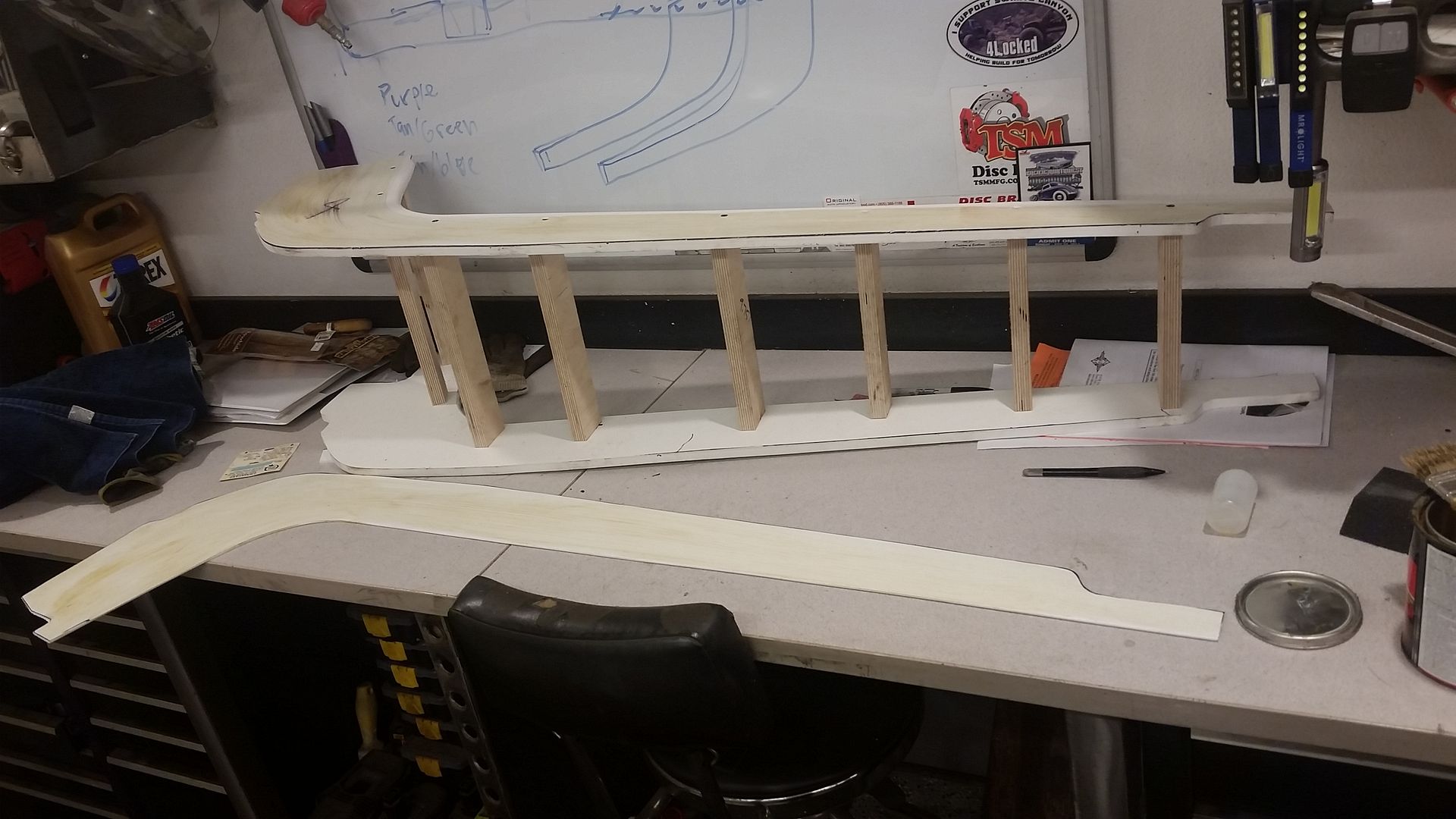

Adding a little detail for the side to break it up. This is 1/8" material.

Cut out, mocked up and letting the glue dry

So this piece serves two purposes. Cover the screw holes that hold the thing together and add a little detail to the top of the side panels. The 1/8" piece is about 3/4" shorter than the side, giving a nice little detail when it is being covered. The side will be covered in one piece each. The center panel will be removable for access to run wiring and things like that down the center. Panel will have a french stitch all the way down the middle to keep the theme on everything.

Going to get the shop all cleaned up and push the truck to the side for a while.

Thanks for following along everyone and offering up your help, I really do appreciate it.

Sean