Good evening Alvin and Jamie, thanks for your fantastic replies!

Alvin in AZ wrote:robroy wrote:Alvin in AZ wrote:

All it needs to is not-rock or move in the process of using it. LOL

I think I'd have to try one of these out to understand this; I can't imagine how a guy would ensure that the dial gauge's rotating axis was perfectly concentric with the crankshaft.

Don't have to be in the center for the "follower" to track a perfect circle.

Anyway, picture drawing a perfect circle in the dirt around a merry-go-round on the school yard.

It doesn't matter if you are standing in the center or not you can still draw any size circle you want. And more important than anything is, if you don't wobble around (been on there too dangged long

the circle around it will be just about perfect.

Gosh Alvin, you're a master at these great analogies--thank you! I understand what you're conveying perfectly and find my previous impression of the situation comical now.

Alvin in AZ wrote:If the ground is uneven then you'll need a "birds eye view" to see the "perfect" circle.

Got it!

Alvin in AZ wrote:Someone standing near the edge reaching all the way across -crooked- with a long stick could draw the same sized perfect circle you could, standing "perfectly" in the center.

Excellent. Understood 100%.

Alvin in AZ wrote:robroy wrote:During Tom's visit last Saturday, he mentioned that he really liked the Browell tool, and planned on ordering one for use in his shop.

In that case, trade it to 'im for a -bucket- full of dial indicators and magnetic bases!

HA! You could be right about this. Some day I'll have an inescapable need to use one of the dial indicators, and I'll probably look back on this with a new understanding.

Alvin in AZ wrote:If you are satisfied with how straight it is, then it's straight enough.

Okay! Thanks so much for your great help.

Alvin in AZ wrote:ps- Who played marbles as a kid and drew a circle around themselves besides me?

pps- I was -good- at marbles, no kidding.

I never played with them! But my parents kept marbles in the freezer at all times. If they could find no other way to get one of us children out of bed in the morning for school, they'd dump in the sack of frozen marbles. It was as effective as it was memorable!

Ranchero50 wrote:Yeah that... You get concentricity because the crank is turning concentricly in the bearing bore so the dial follows the cranks sweep as long as it's not rocking on the mounts.

Okay! Thanks for explaining this. My previous visualization was nonsensical!

Ranchero50 wrote:I was reading the Ford manual for '74 and it has a page dedicated to this, basicly said clean, measure inner bore and face, measure, clean and repeat until it's clean enough to read right. If you can't get the bore runout to .001" toss the bellhousing. You can use shop made shims for the face runout of it's over .001" TIR (total indicator runout). I wanted to bring it into work and scan it but it's still sitting on the counter and I'm here.

Thanks Jamie! Now that you mention this, my 1972 Ford shop manual has a similar section in it. It even has a photo of the dial gauge in action! So I think I'm all set with a reference when the time comes for me to learn more.

Ranchero50 wrote:I'm doing the same thing at work to a cassette module in the folder. Trying to get it right is a pain. You have to use a port-a-power to spread the side frame of the folder apart to get the housing to move, then support that and tap it a couple thou whichever way you want it. I'm about to install some jacking screws so I can hold the height without a chainfall.

You sure have a way with machines Jamie! Your work's impressive. Here I am still trying to understand my key-ring.

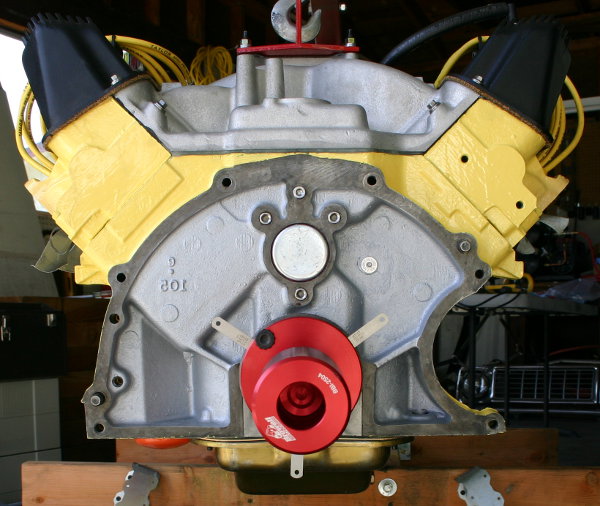

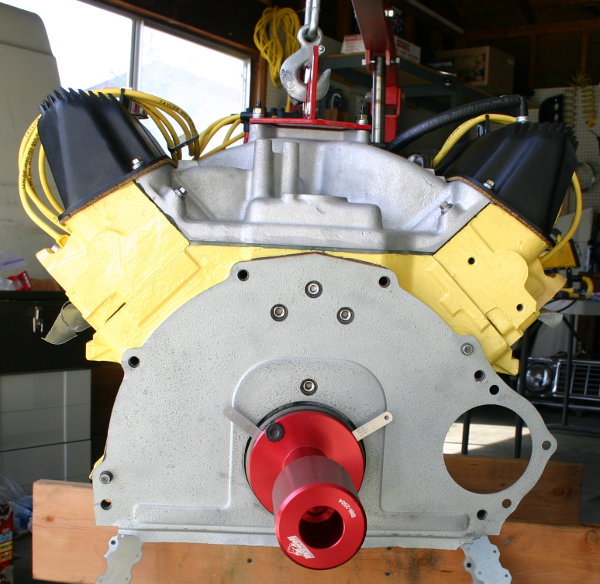

The sun came out today so I was able to take some photos in better lighting!

I re-tested the alignment with the starter plate installed, and found it equally excellent!

Jamie and Alvin, thank you both for taking the time to explain the additional alignment checks that I'm not going to perform this time around. I'm certain that your advice will benefit me in the future when I'm in a similar situation!

Thanks for your quality replies,

Robroy